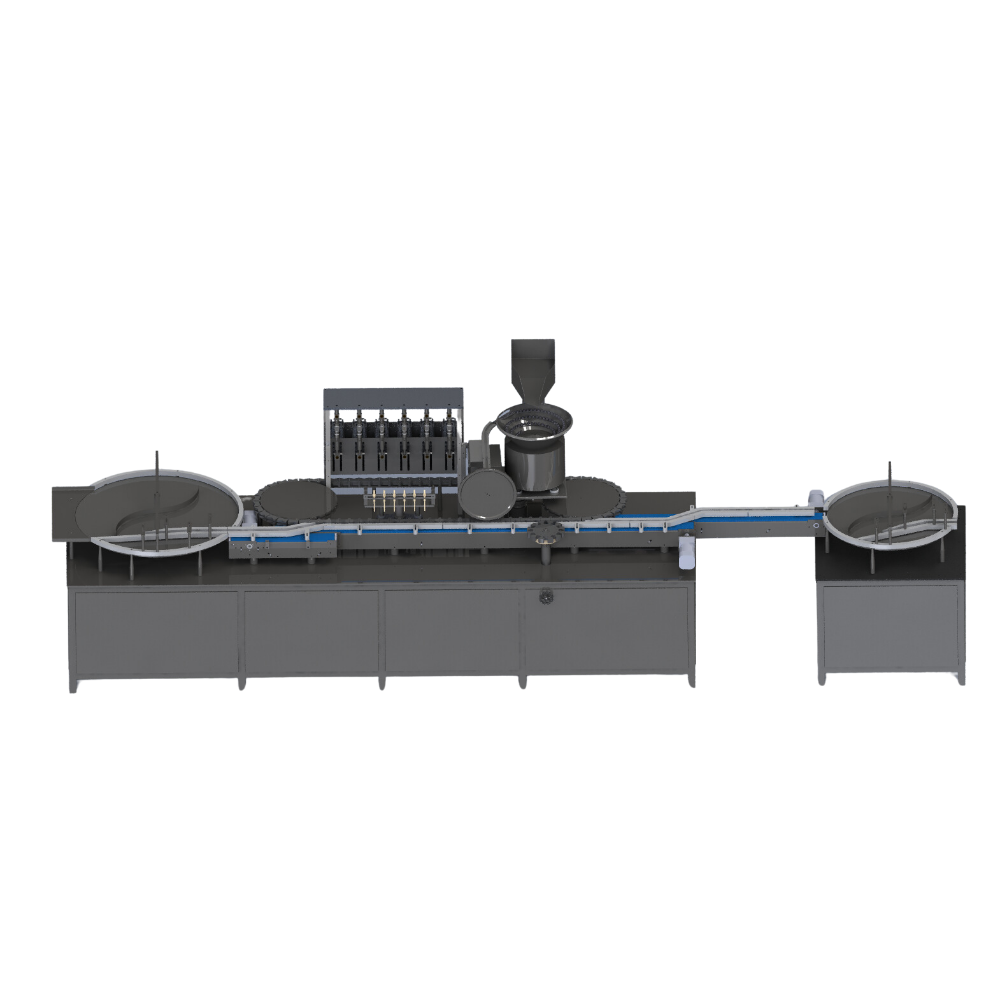

WEIGHT BASED REJECTION INJECTABLE LIQUIDE FILLING MACHINE

Our injectable liquid filling machine, equipped with SCADA operating system and 21 CFR Part 11 compliance, delivers 3,600 vials per hour. It features highly accurate pump-based filling and a weight-based rejection system, ensuring only correctly filled vials proceed.

Production Capacity: up to 24000 Vials/Hr

Our state-of-the-art injectable liquid filling machine is designed to deliver unmatched precision, efficiency, and user-friendliness, making it an ideal solution for high-demand pharmaceutical production environments.

Key Features:

- Highly Accurate Pump-Based Filling:Equipped with advanced pumps, our machine ensures exceptional dosing accuracy, reducing product waste and ensuring consistency across batches.

- High-Speed Multi Head Head System:The machine features a 2-head configuration, capable of filling up to 3,600 vials per hour, making it suitable for large-scale production while maintaining high precision.

- Weight-Based Rejection System:Integrated with a weight-based rejection system, the machine automatically rejects any vials that do not meet the exact fill weight, ensuring only correctly filled vials proceed to the next stage.

- SCADA Operating System with 21 CFR Part 11 Compliance:The machine is equipped with a SCADA operating system, fully compliant with 21 CFR Part 11, providing secure, traceable electronic records and ensuring regulatory compliance.

- Automatic Rubber Stopper with Pick and Place Mechanism:The machine includes an automatic rubber stopper placement system with a pick and place mechanism, ensuring precise and reliable sealing of vials.

- No Rubber Stopper System Rejection:Any vial that does not receive a rubber stopper is automatically rejected, ensuring that only properly sealed products continue through the production line.

- Smooth Machine Operation with Hi-Motion System:Our machine is designed for smooth operation, utilizing the Hi-Motion system to reduce mechanical stress and enhance the longevity and reliability of the machine.

- Easy Filling Volume Calibration:The machine features an easy filling volume calibration system with inbuilt filling volume correction algorithms, allowing for adjustments during operation without halting production.

- User-Friendly Maintenance:All diagnostic data is accessible through the operating system, making maintenance straightforward and reducing downtime. This feature is designed with the user in mind, simplifying routine checks and troubleshooting.

- High-Quality Contact Parts:All contact parts are made of stainless steel (SS) to ensure product safety and compliance with pharmaceutical standards. All change parts are crafted from anti-static, food, and pharma-grade materials, providing durability and ease of cleaning.

- Versatile Isolation Options:The machine can be customized to include CCARBS, OCARBS, or isolator-based containment options, depending on the final order specifications, ensuring flexibility to meet different production requirements.

- This injectable liquid filling machine is a robust and versatile solution designed to meet the rigorous demands of modern pharmaceutical production, combining high-speed performance with precision, safety, and compliance.

- Supply Voltage : 415VAC 3PHASE 50HZ.

- Power Requirement : 5 HP

- Speed : 3600 Vial/Hour (*Based on Machine Features and Filling Number of Head and Filling Volume*)

- Fill Volume : 1ml to 100ml.

- Filling Accuracy : ±1%

- Filling With : High Accuracy Peristaltic Pump.

- No Of Filling Head : 2, 4, 6, 8,12, or 16.

- Type of Rubber Stopper System : Pick & Place Type

- Rubber Stopper : 13mm, 20mm, 32mm.

- Operating System: Industrial PC with 15 Inch Screen Size equipped with Automatic Backup, 21CFR Part 11 Compliance Operating System, Reporting's.

Frequently Asked Questions

What is the production capacity of the injectable liquid filling machine?

The machine has a 2-head configuration capable of filling up to 3,600 vials per hour, making it ideal for high-volume production lines.

How does the weight-based rejection system work?

The weight-based rejection system automatically weighs each filled vial. If a vial does not meet the exact fill weight, it is immediately rejected, ensuring that only correctly filled vials proceed to the next production stage.

Is the machine compliant with regulatory standards?

Yes, the machine is equipped with a SCADA operating system that is fully compliant with 21 CFR Part 11, ensuring secure electronic records and traceability in accordance with FDA regulations.

What features are included for vial sealing?

The machine includes an automatic rubber stopper placement system with a pick and place mechanism. Additionally, vials that do not receive a stopper are automatically rejected to maintain product integrity.

How does the Hi-Motion system enhance machine operation?

The Hi-Motion system ensures smooth operation by reducing mechanical stress, which in turn enhances the longevity, reliability, and performance of the machine.

What materials are used for contact and change parts?

All contact parts are made of stainless steel (SS) to meet pharmaceutical standards. Change parts are crafted from anti-static, food, and pharma-grade materials, ensuring durability and ease of cleaning.

Is the machine customizable to different containment options?

Yes, the machine can be customized with CCARBS, OCARBS, or isolator-based containment systems based on your specific order requirements.

How does the machine ensure easy maintenance?

The machine’s operating system provides access to all diagnostic data, simplifying maintenance tasks and reducing downtime. This user-friendly design ensures efficient and effective upkeep.

What is the warranty period for the machine?

The machine comes with a comprehensive Two-year warranty, providing long-term reliability and peace of mind.

The machine comes with a comprehensive Two-year warranty, providing long-term reliability and peace of mind.

Does the machine support advanced reporting?

Yes, the machine includes advanced reporting features with graphical representation, making it easier to monitor, analyze, and optimize production data.

Yes, the machine includes advanced reporting features with graphical representation, making it easier to monitor, analyze, and optimize production data.

What additional accessories and options are available?

Along with the machine, we offer accessories like conveyors, turntables, and a full range of spare parts to ensure seamless integration into your production line.

Along with the machine, we offer accessories like conveyors, turntables, and a full range of spare parts to ensure seamless integration into your production line.

Does the load cell require recalibration?*

Yes, it is recommended to recalibrate the load cell at regular intervals. Regular recalibration ensures optimal accuracy in filling volume, maintaining the machine's precision and consistent performance. And for this we equipped Operating system with easy Re-Calibration system and system records its data.

Yes, it is recommended to recalibrate the load cell at regular intervals. Regular recalibration ensures optimal accuracy in filling volume, maintaining the machine's precision and consistent performance. And for this we equipped Operating system with easy Re-Calibration system and system records its data.