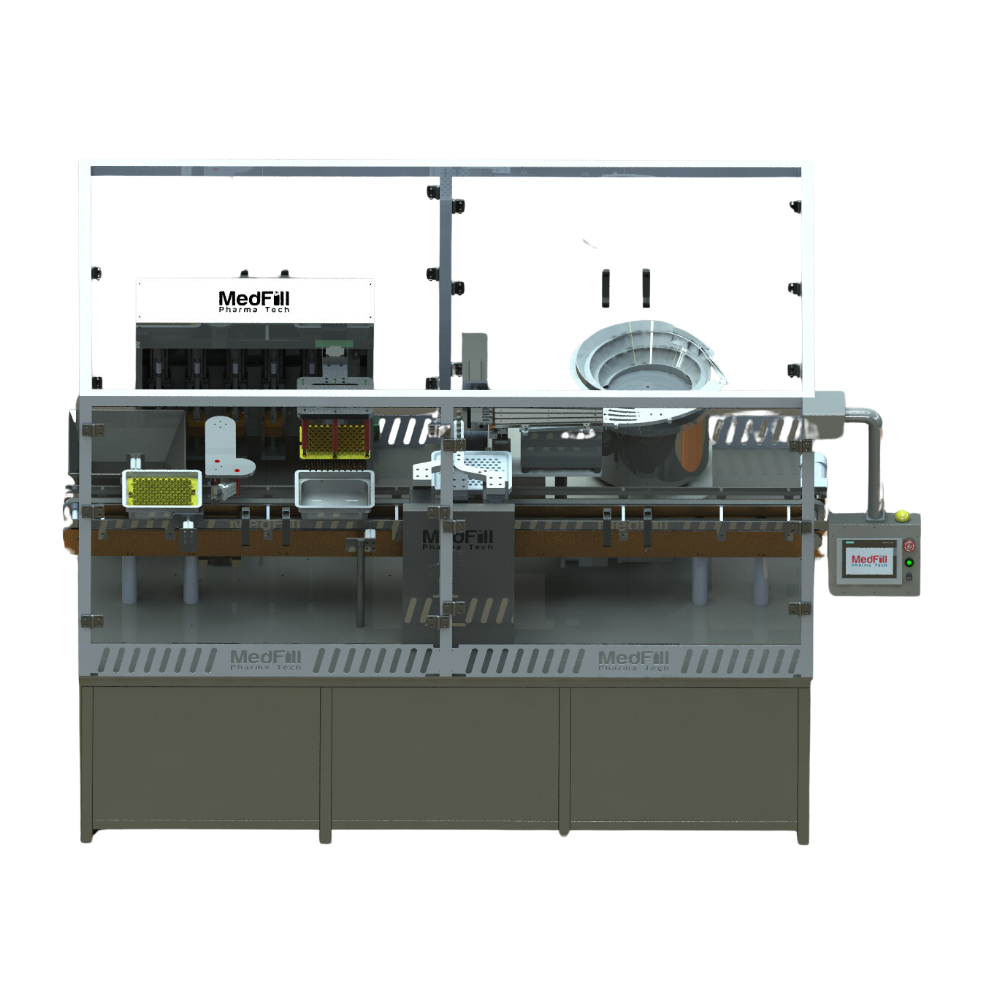

PFS Semi or Fully Automatic Type

MedFill’s PFS machine, configurable with 21 CFR Part 11, offers fully automatic (robotic) or semi-automatic versions. It provides stoppering options (vacuum chamber, bunging), ±1% fill accuracy in 2ml, and speeds of 4500-6000 syringes/hour for 5 filling head. Filling Parastatic

Production Capacity: up to 24000 Vials/Hr

The MedFill Pre-Filled Syringe (PFS) machine is engineered for precision and flexibility in pharmaceutical syringe filling. Designed to meet stringent industry standards, this machine is ideal for both large-scale production and customized batch processing.

Key Features:

- 21 CFR Part 11 Compliance:The machine is configurable to comply with 21 CFR Part 11, ensuring adherence to global regulatory standards.

- Automation Options:

- Fully Automatic Version:Equipped with a robotic system for high-efficiency, non-intervention operations. From Automatic Paper removal to Filling to Stoppering.

- Semi-Automatic Version:Requires some manual intervention, offering a balance between automation and control.

- Stoppering Options :

- Vacuum Chamber Type:Ensures precise and secure stoppering under vacuum conditions.

- Bunging Type:This Stoppering Works without Vacuum Chambers with Help of Stoppering Mechanism.

- Filling Mechanisms :

- Rotary Syringe:Offers consistent and accurate filling.

- High Accurate Peristaltic Pump:Suitable for handling sensitive or viscous liquids, with high accuracy.

- Filling Accuracy:Achieves a filling accuracy of ±1% for filled volume syringes, ensuring consistent dosage and Can be Filled Filling Volume from 0.2ml to 10ml with help of Change Part.

- Head Operation:Available in 2, 5, or 10 head configurations, tailored to meet different production speeds and volumes.

- Production Speed:Capable of processing 4500 to 6000 syringes per hour with 5 Head Filling Operations, maximizing productivity while maintaining accuracy.

- Supply Voltage : 415VAC 3PHASE 50HZ.

- Power Requirement : 5 HP

- Speed : 4500 TO 6000 Syringe/Hour (*Based on Machine Features and Filling Number of Head and Filling Volume*)

- Fill Volume : 0.2ml to 10ml..

- Filling Accuracy :±1%

- Filling With: High Accuracy Peristaltic Pump or Rotary Syringe.

- No Of Filling Head :2, 5, 10.

- Type of Stoppering System:Pick & Place Type OR Vacuumed Chamber Type

- Operating System :Industrial PC with 15 Inch Screen Size equipped with Automatic Backup, 21CFR Part 11 Compliance Operating System, Reporting's.

Frequently Asked Questions

What kind of stoppering systems do you offer?

We offer "Pick and Place Type" and "Vacuum Chamber Type" stoppering systems, based on the specific requirements of your production process.

Can the machine be configured with LF, RABS, or an Isolator?

"Yes", the machine can be configured with Laminar Flow (LF), Restricted Access Barrier Systems (RABS), or an Isolator, depending on your operational and regulatory needs.

What functions are covered in the fully automatic version?

The fully automatic version includes "nest paper removal, filling, and stoppering", all managed through advanced robotic motion. This automation minimizes human intervention and maximizes efficiency.

What is the difference between the semi-automatic and fully automatic versions?

In the "semi-automatic version", after the filling process, the operator manually places the nest in the vacuum chamber for stoppering. In the "fully automatic version", all processes, including nest handling, filling, and stoppering, are fully automated and controlled by robotic systems.

What kind of filling methods do you use?

We use highly accurate "Peristaltic Pump" or "Rotary Syringe" filling methods, selected based on the customer's User Requirement Specification (URS).

What is the filling accuracy of the machine?

We provide a filling accuracy of "±1%" of the filled volume. For example, if you are filling 2ml, the variation will be within "±0.02ml".

What is the filling volume range the machine can handle?

The machine is designed to handle various filling volumes, customizable based on specific production needs.

How many heads are available, and what is the production speed?

The machine can be configured with "2, 5, or 10 heads, depending on your production requirements, with speeds ranging from ""4500 to 10000 syringes per hour".

What types of syringes can the machine fill?

The machine is versatile and can fill a wide range of pre-filled syringe types, including both standard and custom-designed syringes.

Can the machine be integrated with SCADA systems?

*Yes, the machine supports integration with SCADA systems and is fully compliant with **21 CFR Part 11*, ensuring adherence to global regulatory standards.

What kind of maintenance is required for the machine?

Routine maintenance includes regular checks of moving parts, calibration of filling mechanisms, and cleaning. We recommend scheduled servicing by qualified technicians to ensure optimal performance.

Is there a warranty for the PFS machine?

"Yes", the machine comes with a comprehensive warranty, which covers parts and labor for a specified period, providing long-term reliability and peace of mind.

Can the machine be customized to meet specific production requirements?

"Yes", we offer a range of customization options to meet your specific needs, including different stoppering systems, filling methods, and automation levels.